|

|

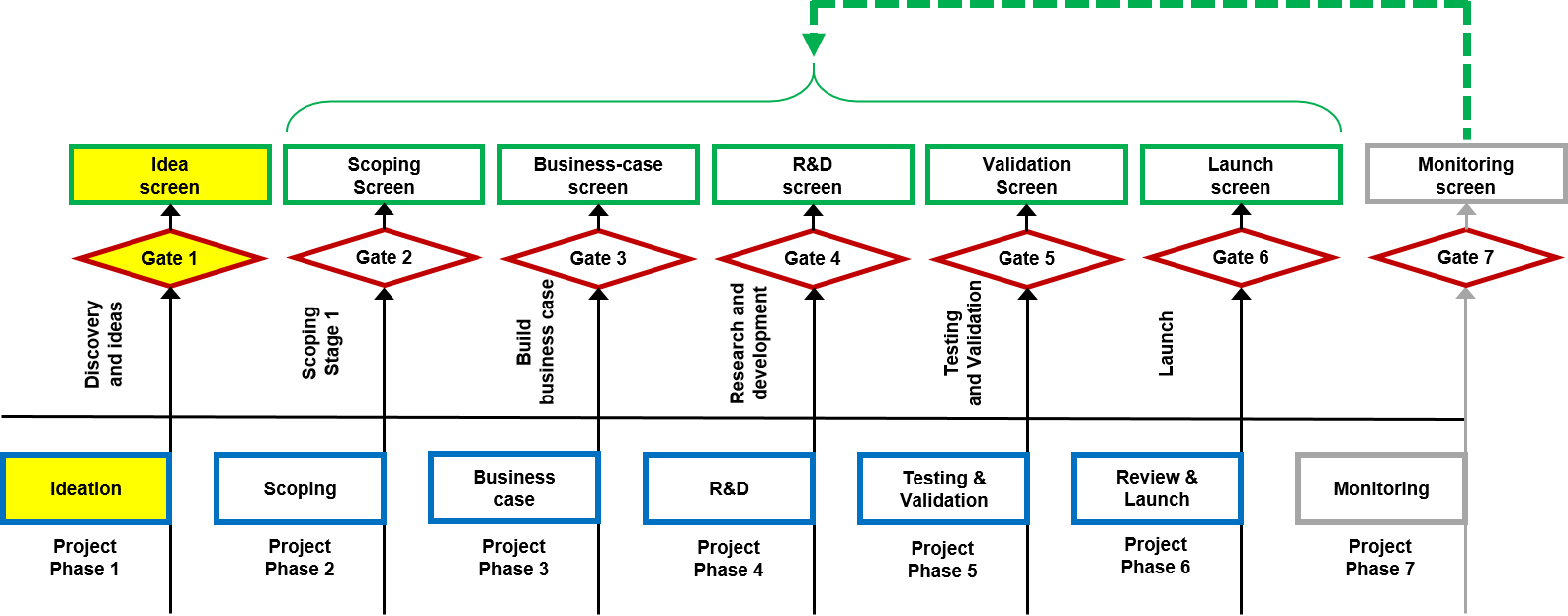

Phase 1: Ideation After conception of the principle idea, a formal idea development phase is established to develop the idea further. This may be done in collaboration with a relevant manager or a first consultation with the governance board.

A formal brainstorming event should be made that considers the technical possibilities of the nanomaterial / nanoproducts / or newly discovered market opportunities and associated opportunities. The brainstorming even may be restricted to an internal event, but it may also involve brainstorming, surveys and workshops with representative business partners, potential users and costumers to develop the idea with their input and investigate market potentials and possible reservations.

It may be valuable to investigate whether there are demanding regulatory documentation requirements or policies that could block or have negative effects on the material or product acceptance (e.g., explosivity; physical shape and characteristics similar to asbestos and carbon nanotubes; and high exposure potential during use or accidental release).

Depending on available information on materials and products, it may be possible to conduct a basic human and environmental pre-risk assessment and pre-risk-benefit evaluation from the use of tools or a basic questionnaire on health and environmental risk indicators. The assessments may initially be performed as internal idea-screen assessments and can be used as part of the documentation for the first stage gate board meeting.

When the idea is sufficiently developed, it is summarized for reporting along with any other project information, (e.g., initial risk assessements, cost-benefit, and regulatory requirements) generated in ideation phase. A review meeting is established with the management or already established risk-innovation governance board where the idea is presented and discussed for a “Go” / ”Rework” / “No Go” decision.

|

|

| Gate 1: Idea screen The idea gate is typically the first time a decision is taken on whether specific resources should be committed to develop the idea further by scoping. This is generally a “soft” gate decision as uncertainty is normally still high and a more clear decision can be made after the scoping phase. The project should be evaluated principally on whether it is aligned with the general strategy and business of the organization, as well as whether the idea is viable and appears to offer good opportunities. If the decision ends with a “go”, it marks the formal beginning of a new innovation project.

|

|

|

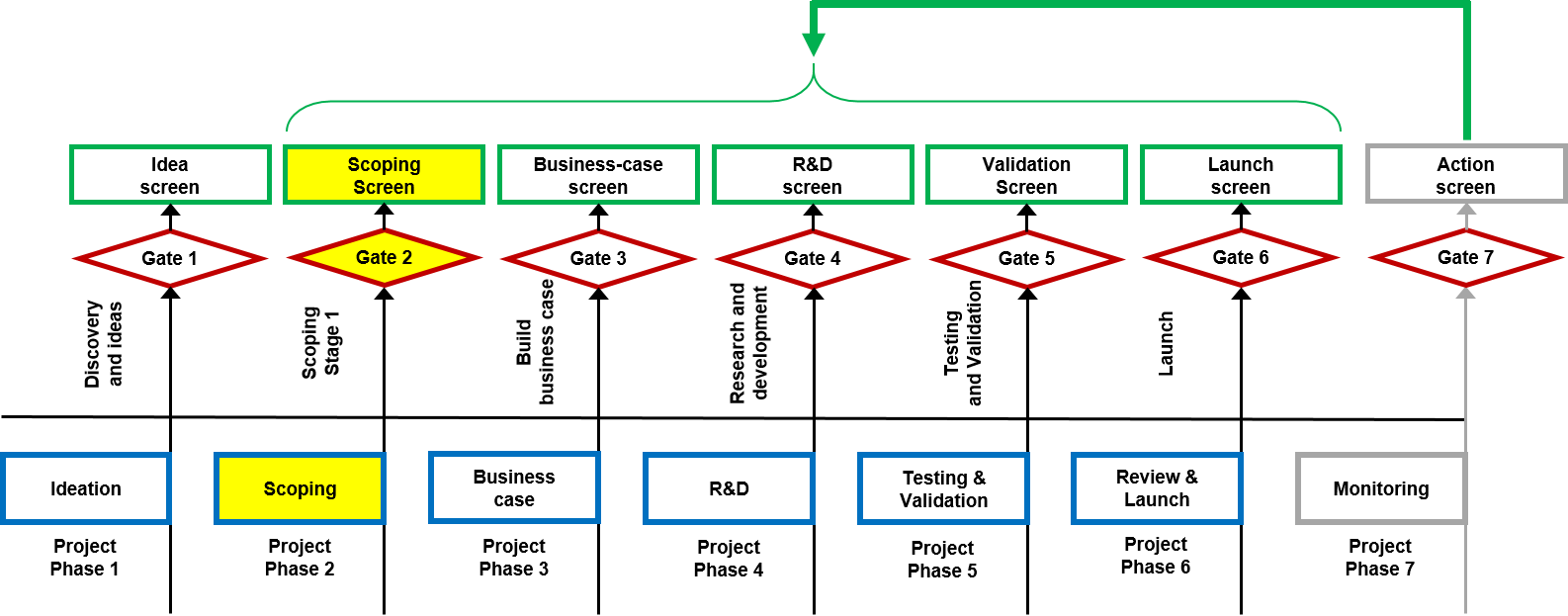

Phase 2: Scoping

During scoping, the main goal is to perform a preliminary technical and market assessment of the nanomaterial / nanoproduct. Immediate health and safety aspects of the nanomaterial and/or nanoproduct should be also investigated by mapping of and using existing knowledge and data.

Determine strengths and weaknesses of the intended nanomaterial / nanoproduct and benefits that downstream users and consumers will experience are identified. In this step, the viability of the technical development and production should be considered, including cost estimates. In addition, challenges and threats to the innovation are also identified, including consideration of potential existing or emerging competition and market acceptance.

If not performed in the previous stage, brainstorming events, surveys or workshops should be organized with key business partners, representative downstream users and/or costumers to further develop the idea with their input and investigate market potentials considering also their risk perception and risk acceptance. A particular part of the stakeholder interaction should be made to obtain information on nano-specific aspects. Workshops and dialogues with a broader suite of stakeholder groups may be needed depending on the novelty and complexity of the potential risks and benefits.

If not completed in the first ideation phase, it is strongly recommended to perform a basic human and environmental pre-risk assessment / pre-risk-benefit evaluation. If a pre-risk assessments or pre-risk-benefit evaluations were already performed in the idea phase, the data and assessments should be reviewed and updated as needed. As part of any of the risk assessment exercises, SSbD and STOP options should be considered and described.

It may be beneficial to include a first assessment of potential production, risk management and mitigation costs as well as whether there are demanding regulatory documentation requirements or policies that could block or have negative effects on the material or product acceptance (e.g., explosivity or physical shape and characteristics similar to asbestos and carbon nanotubes).

When the scope is fully explored, it is documented and summarized in a report for the next review meeting with the nano-risk innovation governance board for for a “Go” / ”Rework” / “No Go” decision.

|

|

|

Gate 2: Scoping screen

The scoping screen decision is based on a further elaborated description of the idea as described in the innovation project scoping stage 2. The principle technical description of the nanomaterial or nanoproduct along with a primary market and viability assessment should be made in a satisfactory manner. Safe and Sustainable by Design options should be considered if possible.

|

|

|

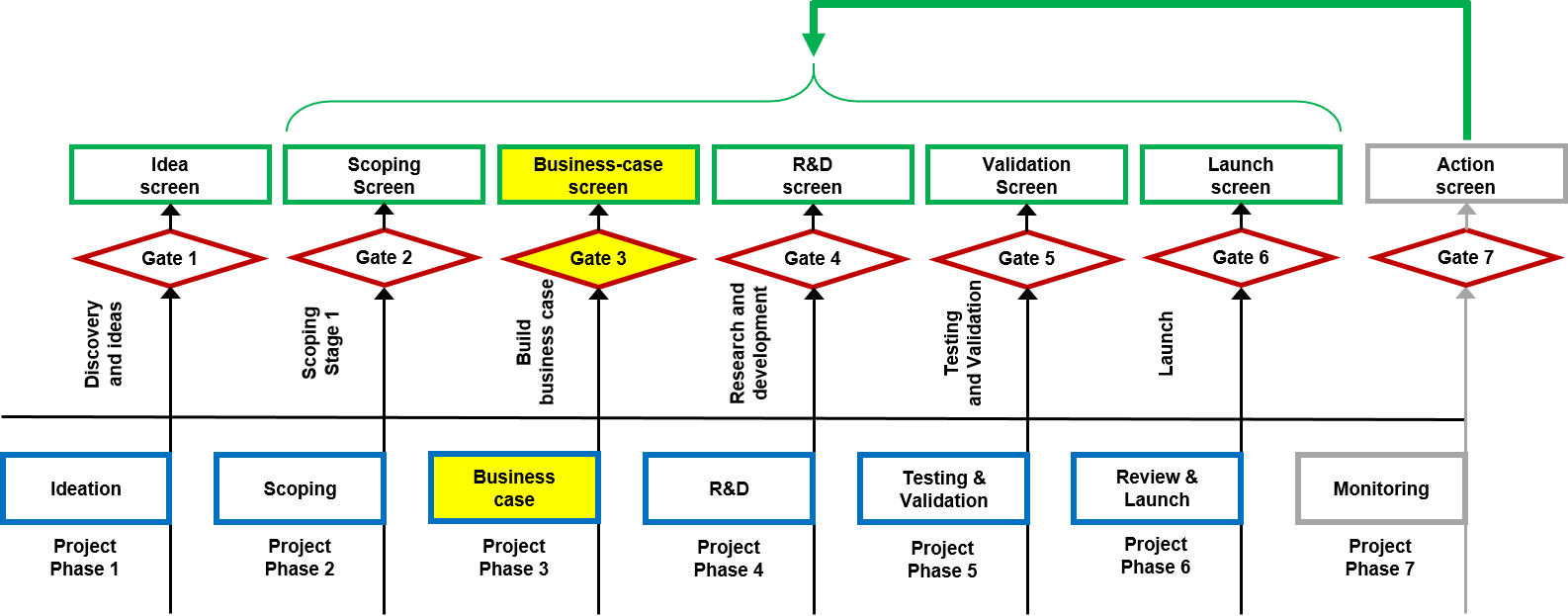

Phase 3: Business case development phase In this project phase, the business case and the business plan are detailed, all relevant pre-risk assessment questions are completed, and full chemical substitutions and Safe and Sustainable by Design (SSbD) and STOP options are considered. It is important that subprojects in this phase are completed as thorough and complete as possible to make the best possible foundation for an informed decision at the next phase-gate review meeting.

The business case development includes, for example: 1) technical analysis; 2) full worker, consumer and environmental pre-risk assessment 3) building financial business case; 4) building project plan; and 5) feasibility review.

The technical analysis consists of the definition of the nanomaterial and/or nanoproduct as well as all technical requirements for the manufacturing. The analysis may include some design or laboratory work to define the nanomaterial and/or nanoproduct; and SSbD options; and the viability of the intended manufacturing processes.

A full occupational and environmental pre-risk assessment must be completed for the intended nanomaterial / nanoproduct as well as for potential substitution and SSbD alternatives. This assessment may require theoretical or experimental hazard and ecotoxicity screening testing. Clear occupational and environmental risk management and worker instruction plan needs to be prepared for discussion at the review meeting.

A down-stream professional user, consumer, and environmental pre-risk assessment / pre-risk-benefit evaluation should also be completed at this stage considering nanomaterial / nanoproduct options. If pre-risk assessments were performed in these domains in the scoping stage, check whether new information has emerged and improve the pre-risk assessments if possible.

If a high-risk-impact on manufacturing or use can occur, it is necessary to include a more detailed assessment of potential accident risk mitigation and management costs as well as to whether there are special and / or demanding regulatory documentation requirements to allow dissemination of the material or product on the market.

Based on the retrieved data, identify anticipated needs for further documentation of technical characteristics, performance and full risk assessment of the nanomaterial / nanoproduct to be in regulatory compliance during both innovation and at launch. This mapping should also consider the needs for further change in insurance and dialogue with specific stakeholder groups.

The economic business case includes a market analysis where the competition is identified and concept testing is performed with the downstream users / costumers to determine their needs and product acceptance. Furthermore, estimations of the investments necessary to generate missing data, start production, develop patents, and comply with regulations and policies are needed. It is recommended that the most critical parameters are identified by a sensitivity analysis or diagnostic if-then or what if analysis.

Next, the project plan from R&D to project launch is drafted, detailing the specific project needs considering the subprojects required reaching full documentation.

It is suggested that the products developed during the business case phase include: 1) definition of nanomaterial / nanoproduct and its intended technical description with SSbD options; 2) draft technical data sheets; 3) draft safety data sheets; 4) a draft manufacturing strategy; 5) an occupational, consumer, and environmental pre-risk assessment; 6) an internal risk communication and training plan; 7) stakeholder survey results on product acceptance and a societal impact assessment; 8) an economic business case including market analysis, production cost estimates and risk-benefit analysis; 9) a project plan from R&D to launch; and 10) an overall feasibility assessment.

The project phase results are documented and summarized in a report for the next review meeting with the nano-risk innovation governance board for for a “Go” / ”Rework” / “No Go” decision.

|

|

|

Gate 3: Business-cased screen

Gate 3 is a very important decision gate as it is the final checkpoint before the moving into the more costly development phase. A careful examination of all the information is conducted both in regards to likelihood and validity of the information provided.

The nanomaterial / nanoproduct (SSbD candidates) show good potential. Necessary major changes are discussed and determined, concerning the design options, development process, but also in terms of the financial analysis. Other factors of specific relevance should be included as needed.

If the project continues, make a careful selection the next stage-gate subprojects, critical questions, and their evaluations.

|

|

|

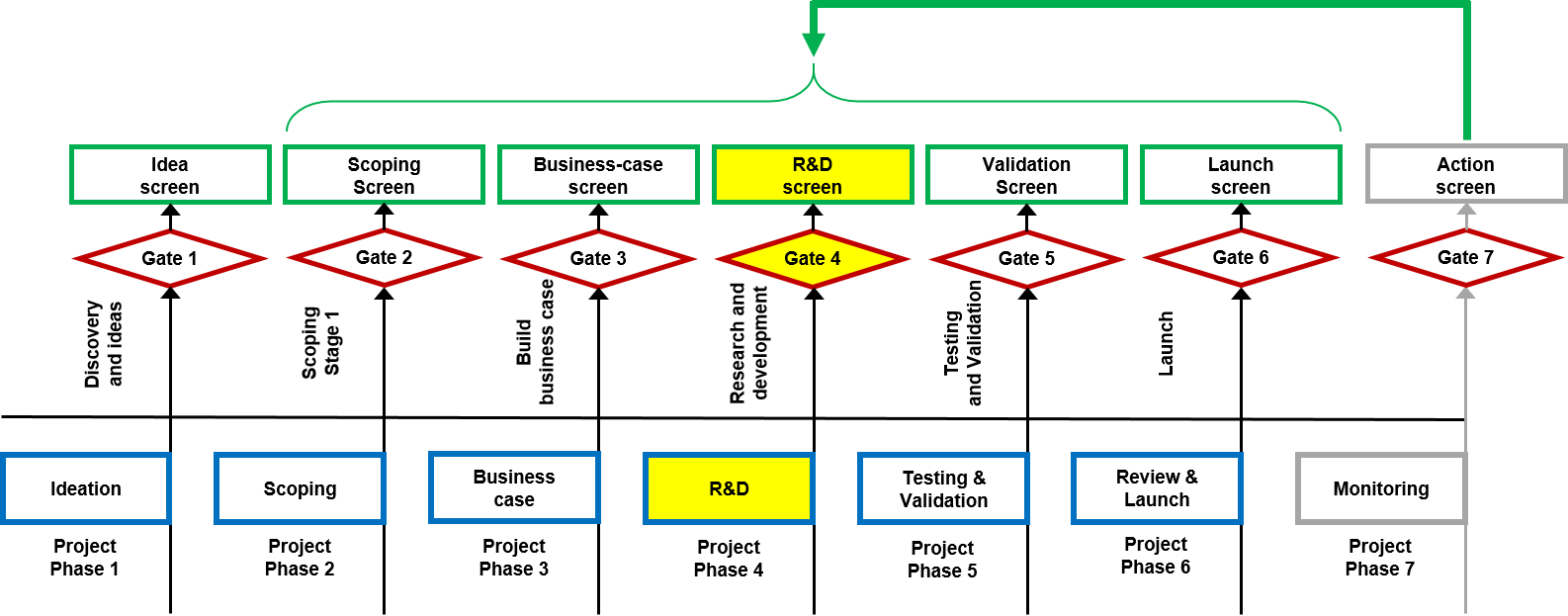

Phase 4: Research and development (R&D)

During the R&D project phase, the nanomaterial / nanoproduct is developed to prototype and the manufacturing will go from laboratory scale to upscale production. The process will potentially have several interim reviews and optimization processes.

The nanomaterial and possible intermediates and/or nanoproducts will be tested for relevant technical parameters and key risk-related aspects. This testing should also include also testing of potential SSbD alternatives and STOP solutions. Some early downstream user / customer testing may be made. Key critical technical and safety data are generated on the specific nanomaterial / nanoproduct (and SSbD options if relevant), considering information requirements for regulations and risk assessment, if such data were not identified during in the previous project phases. The nanomaterial / nano-product marketing and production plans are also developed.

Before starting any R&D work, an occupational and environmental pre-risk assessment; waste handling strategies; and all instruction and worker training should be completed. Risk communication and training should also be prepared and held for cleaning staff and external contractors if they also work in the facility. In parallel, further risk-assessment may be made for the nanomaterial / nanoproduct in its downstream use.

If a high-risk-impact on manufacturing or use can occur, it is necessary to include a more detailed assessment of potential accident risk mitigation and management costs as well as to whether there are special demanding regulatory documentation requirements to allow dissemination of the material or product on the market.

It is suggested that the products of the development phase include: 1) the prototype of the nanomaterial / nanoproduct with full technical documentation of SSbD and STOP options; 2) a draft technical data sheet; 3) a draft safety data sheet; 4) a full-scale production plan; 5) a draft occupational, consumer, and environmental risk assessment; 6) an internal and draft external risk communication and training material; 7) an updated risk-benefit analysis; 8) a draft marketing plan; and 9) a horizon scanning risk-monitoring report.

The project phase results are documented and summarized in a report for the next review meeting with the nano-risk innovation governance board for for a “Go” / ”Rework” / “No Go” decision.

|

|

|

Gate 4: Research & development screen The nanomaterial / nanoproduct (SSbD candidates) lives up to the expected criteria, quality. Necessary major changes are discussed and determined at this point, concerning the design options, development process but also in terms of the financial analysis. Other factors of specific relevance should be included as needed.

|

|

|

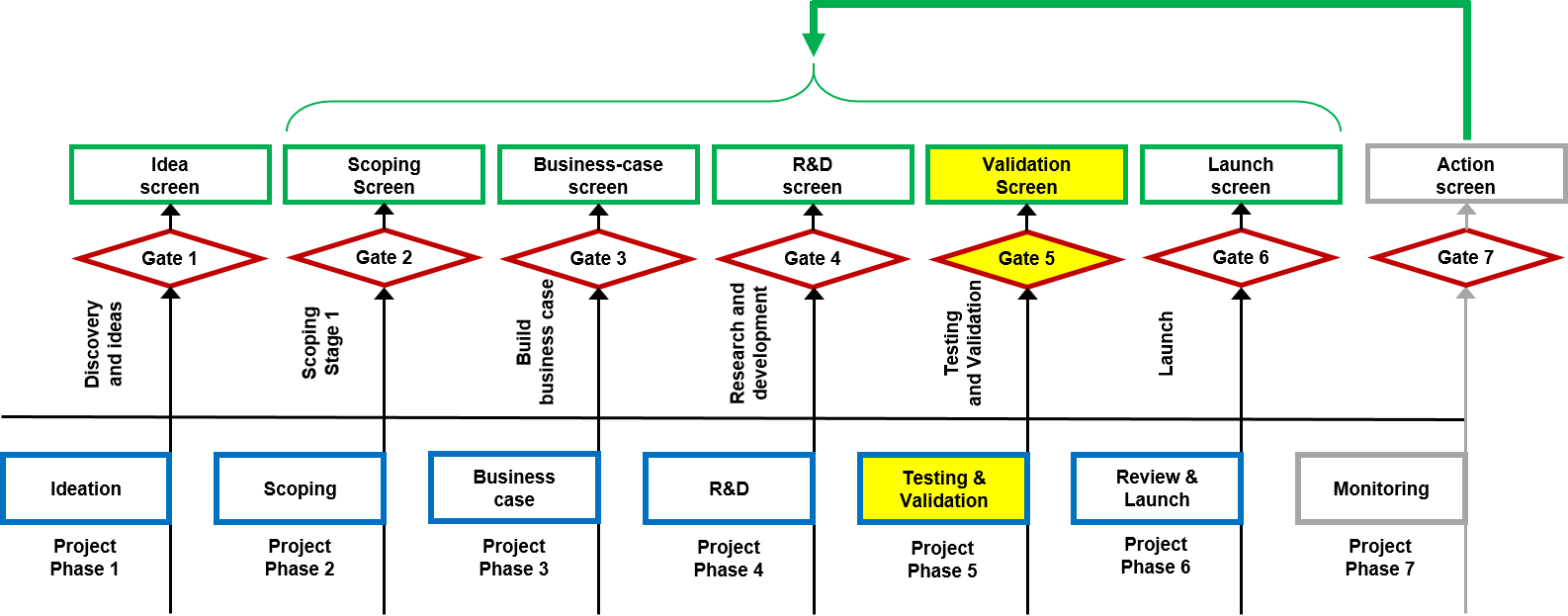

Phase 5: Testing and validation The entire project is evaluated and validated considering for example: 1) the technical state, data and performance of the nanomaterial / nanoproduct; 2) the production / manufacturing process; 3) the occupational, user / consumer and environmental risk assessment and mitigation plans along the value chain and product life-cycle; 4) final compliance testing with all relevant regulations and policies; 5) validation of downstream user / customer interest and acceptance, 6) a societal and ethical impact assessment; and 7) the financial value of the project.

The final nanomaterial and/or nanoproduct SSbD and STOP option should be selected at this stage if not done earlier. Potentially remaining technical and safety data are generated to comply with the information requirements for full technical documentation, risk assessments and registration of the nanomaterial or nanoproduct at relevant authorities and registers.

A full risk assessment of the final nanomaterial / nanoproduct should now be made if not completed in the previous stage.

The full-scale manufacturing process is developed and validated.

Full occupational and environmental risk assessment must be completed and all instruction and all instruction and worker training should be completed before any work is initiated at this stage. Risk communication and training should also be prepared and held for cleaning staff and external contractors if they also work in the facility.

Stakeholder interaction events are completed to recheck the market interest for the final nanomaterial / nanoproduct and to assess potential societal and ethical impact, which may need mitigation.

If a high-risk-impact on manufacturing or use can occur, it may be necessary to include a more detailed assessment of potential accident risk mitigation and management costs as well as to whether there are special demanding regulatory documentation requirements to allow dissemination of the material or product on the market.

At the end of this phase all documentation and assessments should be drafted for stage-gate review: 1) the final nanomaterial / nanoproduct with full technical documentation; 2) a technical data sheet; 3) a safety data sheet; 4) description of the full-scale production plan and capacity; 5) a full occupational, consumer, and environmental risk assessment with instruction for safe use and disposal; 6) an internal and external risk communication plan and training material; 7) an final risk-benefit and societal impact analysis; 8) a pre-registration report at REACH and other relevant authorities as needed; 9) a final marketing plan; and 10) a risk-monitoring strategy.

The project phase results are documented and summarized in a report for the next review meeting with the nano-risk innovation governance board for for a “Go” / ”Rework” / “No Go” decision.

|

|

|

Gate 5: Validation screen

This is the final screen before launching the nanomaterial / nanoproduct production. All results from validation and testing are accepted and the quality of the validation and testing stage results are satisfactory. The detailed marketing plan as well as the operations plan are approved at this gate.

|

|

|

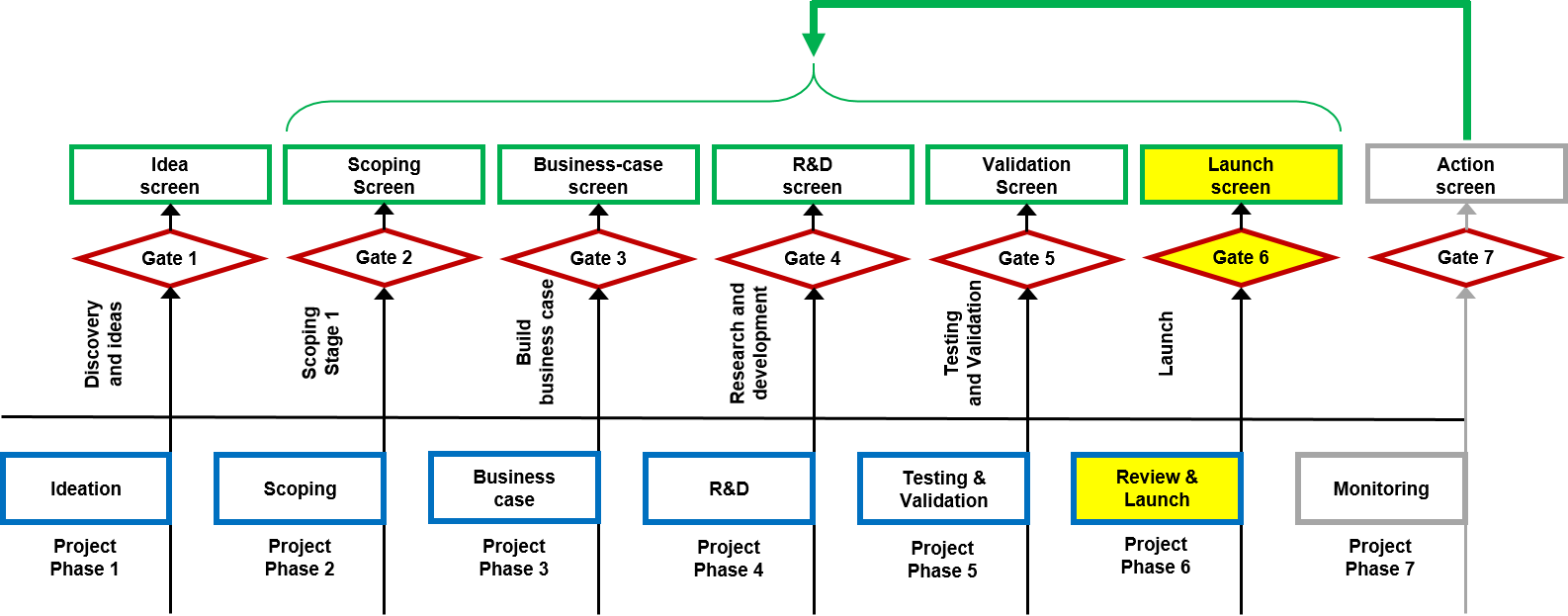

Phase 6: Review and launch

When the final nanomaterial / nanoproduct is accepted for launch, all data are reviewed and updated if needed for internal and external approval (e.g., authorities, insurance, and registries).

All technical and safety data sheets are finalized as well as all documentation that will be used for internal and external risk communication.

Full occupational, product, consumer and environmental risk assessment is completed followed by instruction and training of the workers before full production is initiated.

Data and requested information are submitted for completion of registration at relevant authorities

A marketing strategy is developed for the nanomaterial / nanoproduct.

Product price is set and sales and support personnel are trained to be familiar with the nanomaterial / nanoproduct.

The production facility is established and the production and sales is initiated.

|

|

|

Gate 6: Launch screen

This is the final approval before launching the product. No critical issues remain. All occupational, down-stream user, consumer and environmental risk assessment data are in compliance with existing and emerging policies and regulations and current nano-risk knowledge. The marketing plan as well as the operations plan are satisfactory.

|

|

|

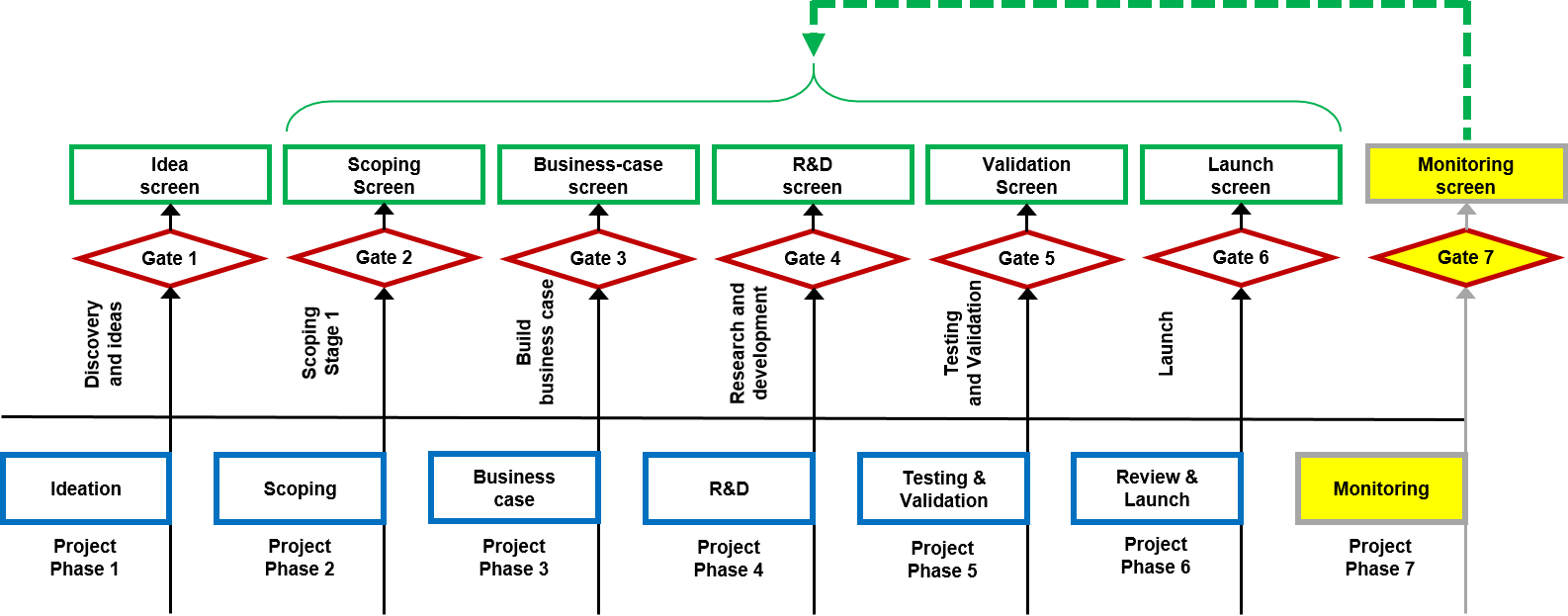

Phase 7: Portfolio monitoring

After launch, the new nanomaterial or nanoproduct becomes part of the product portfolio of the company and the product is monitored with regular follow-up. Examples of responsibilities for portfolio management are given in ISO21505:2017 Project, programme and portfolio management – Guidance on Governance. The production is governed by occupational and environmental risk assessment and management according to ISO45001:2018 Occupational health and safety management systems – Requirements with guidance and use and ISO31000:2009 Risk management – Principles and guidelines.

Special monitoring attention should be made to react to new knowledge on human and environmental health risks caused by the specific nanomaterials produced or used. An emerging risk monitoring procedure should be established considering the relevant nanomaterial and / or nanoproduct, manufacturing processes, regulations, labelling, and nano-risk aspects according to a PDCA (Plan-Do-Check-Act) concept. This is to allow continual improvement of the product performance as well as the human and environmental safety during production, use, and disposal. The PDCA approach is for example described according to occupational health and safety management in ISO 45001:2018 Occupational health and safety management systems – Requirements with guidance for use.

|

|

|

Gate 7: Monitoring screen

At this stage the project has been transferred to portfolio management and is monitored as part of the established productions in the organization. Results from user feed-back, market reports and tailored horizon scanning are monitored and reviewed periodically as defined by the organization and actions are made considering continuation, adjustment or stop of sales and/or production. Information related to worker, consumer and environmental safety is followed by horizon scanning and reviewed by default at least every six months to ensure timely corrective actions following the PDCA concept.

|